How To Choose The Vitrified Grinding Wheels ?

Here you will find bench grinding wheels, tool room wheels, and production grinding wheels in some common sizes of various grit types, grit sizes, and hardness. Please inquire about others that were not listed here. In most cases, we stock several close variations of the same wheel: For example, if we only show a 60 grit ‘I’ hardness for a particular size, we probably carry an ‘H’ and a ‘J’ hardness and a 46 and 80 grit too.

Typically, we stock grit ranges from 36 to 150 and hardness from ‘H’ to ‘L’. Also, we can custom design and have manufactured most any wheel to your needs. Pricing is generally a little higher for this service and lead time are a little longer (up to 6-8 weeks), but you are assured of getting exactly the correct wheel for your unique application. Please send your requirements to us for pricing.

Application: | Grain: | Size: |

- Steel Industries

- Bearing Industries

- Fabrication Units

- Non Ferrous Industries

- Precision Grinding Industries

- Tool Room Wheels

- Our Range Covers

| - Silicon Carbide Wheels

- White Aluminum Oxide Wheels

- Brown Aluminum Oxide Wheels

- Pink Aluminum Oxide Wheels

- Various Combination of The Grains in Vitrified and Resinoid Quality

| - Diameter : 12mm to 750 mm

- Thickness : 3.2 mm to 312 mm

- Bore : 3 mm to 304.5 mm

|

※Major type:

Sorted by color

⑴ Grey Wheels

Premium A/O Semi-Friable Grain.

Used primarily for bench and pedestal offhand grinding of H.S.S Tools

⑵ Green Wheels

Premium silicon carbide grain.

Used primarily for bench and pedestal offhand grinding of carbide and ceramic tools.

⑶ White Wheels

Premium friable grain.

Used primarily for grinding hard tool steels.

Cool cutting on heat sensitive material.

Light stock removal, .001 or less per pass.

⑷ Pink Wheels

Premium A/O light bright pink grain.

Primarily used for surface grinding of high content chrome steel.

Excellent for use on heat sensitive materials and exotic alloy materials

⑸ Ruby Wheels

A/O dark red color.

Excellent for use in tool and cutter grinding as well as surface grinding of steel tools.

⑹ Orange Wheels

Premium A/O grain with clay induced bond.

Fires out orange to brick red.

Used for tool grinding when trying to hold a radius or sharp corner.

May also be used when form grinding.

⑺ Blue Wheels

Ceramic grain.

Available in 20% thru 50% mixtures with premium A/O grains.

Excellent for grinding steels with 40 or greater Rockwell hardness.Faster stock removal with longer wheel life

Sorted by Shape

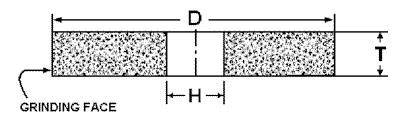

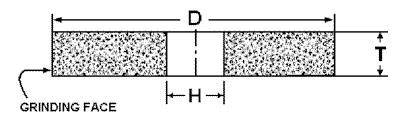

| Type 1 (P): Straight Grinding Wheel |

| Used For Surface grinding, Cylindrical grinding, Internal grinding |

|  |

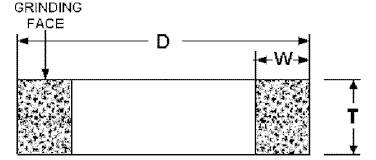

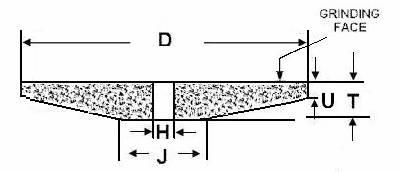

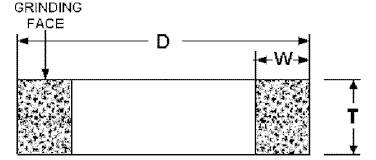

| Type 2 (N): Cylinder Grinding Wheel |

| Used for Vertical Spindal surface grinding |

|  |

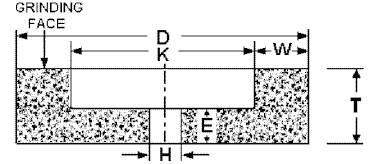

| Type 6 (PDA): Straight Cup Grinding Wheel |

| Used on Vertical Spindle surface grinders for cutter grinding and off hand grinding of tipped tools. Also used on portable machines generally, with a threaded safety bush |

|  |

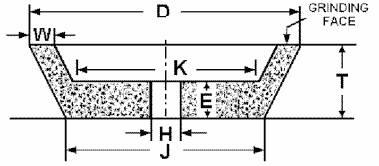

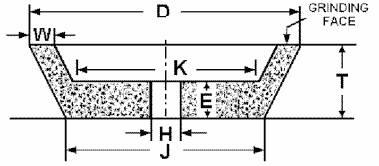

| Type 11 (BW): Taper Cup Grinding Wheel |

| Used for cutter grinding. Also used on portable machines, generally with a thread bush |

|  |

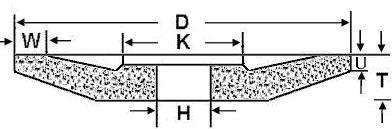

| Type 12a / 12b (D1/D3): Dish Grinding Wheel |

| Used for tool room operations, where its shape enables it to be used in narrow places. |

|  |

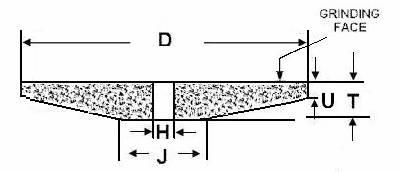

| Type 3 (PDX): Wheels Tapered One Side |

| Used for sharpening wood cutting saw blades commonly called saw gumming wheel. |

|  |

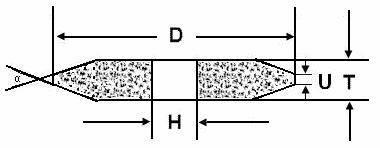

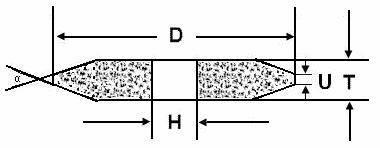

| Type 4 (PSX): Wheels Tapered Two Sides |

| Used for sharpening gear and its surface, and mongline worm |

|  |

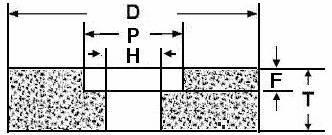

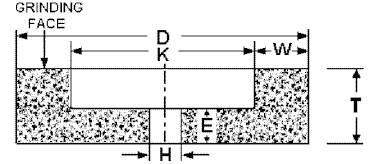

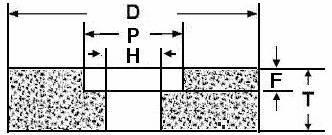

| Type 5 (B): Single Recessed Grinding Wheel |

| Used for surface, cylindrical, internal and off- hand tool grinding. The recess is to accomodate mounting flanges |

|  |

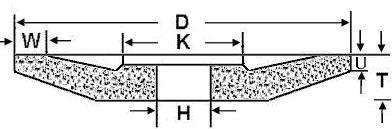

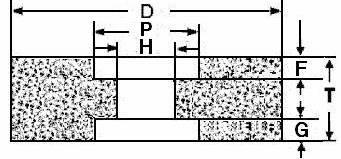

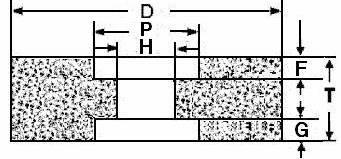

| Type 7 (PSA): Double Recessed Grinding Wheel |

| Used for surface, cylindrical and off-hand grinding. The recesses are to accomodate the mounting flanges to facilitate off-hand grinding of tipped tools. |

|  |